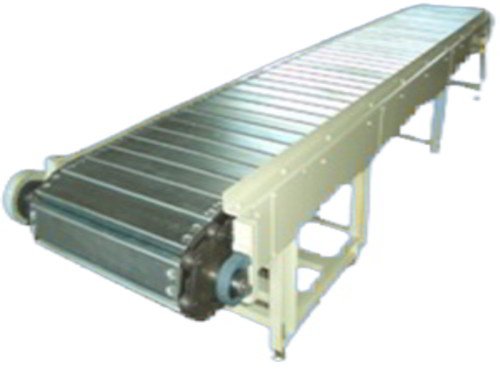

Conveyor systems have become an essential part of various industries, including manufacturing, warehousing, and distribution. Flat belt conveyors, in particular, are widely used in various applications due to their simplicity and reliability. Dev Engineering is one of the leading flat belt conveyor manufacturers in India, known for its high-quality products and innovative solutions.

When it comes to flat belt conveyors, Dev Engineering is a name that stands out. The company has been in the industry for many years and has built a reputation for delivering top-notch products and services. the leading Dev Engineering Flat Belt Conveyor Manufacturers in India:

Flat Belt Conveyor Specification

Flat belt conveyors are used in various industries and applications to transport goods, materials, and products. The specifications of a flat belt conveyor can vary depending on the application, but some common specifications include:

- Belt width: The width of the belt can range from a few inches to several feet, depending on the required capacity.

- Belt length: The length of the conveyor can vary from a few feet to several hundred feet.

- Belt material: Common belt materials include rubber, PVC, polyester, and more. The choice of material will depend on the type of goods being transported, the environment, and other factors.

- Belt speed: The speed of the belt can vary from a few feet per minute to several hundred feet per minute, depending on the application.

- Load capacity: The maximum weight that the conveyor can carry will depend on the specifications of the conveyor, including the belt width, material, and support structure.

- Drive mechanism: The drive mechanism can be an electric motor, gearbox, pulley system, or another type of mechanism depending on the specific requirements of the application.

- Frame and support structure: The conveyor frame and support structure can be made of metal, plastic, or another material, and will be designed to support the weight of the goods being transported and the conveyor components.

This is a general list and the specifications may vary based on the specific requirements of the application. It is best to consult Dev Engineering for your specific needs and correct specifications.

Understanding Flat Belt Conveyors

it’s important to understand what flat belt conveyors are and how they work. Flat belt conveyors are simple, reliable, and cost-effective conveyor systems that are widely used in various industries. They consist of a flat belt that is supported by a series of pulleys and powered by an electric motor.

These conveyors are ideal for transporting light to medium-weight materials, such as packages, boxes, and pallets. They’re also used for a wide range of applications, including assembly lines, material handling, and product sorting.

Features and Benefits of Flat Belt Conveyors

There are several features and benefits of flat belt conveyors that make them a popular choice for various industries. Here are some of the most notable:

- Simple design: Flat belt conveyors have a simple design that makes them easy to install, maintain, and repair.

- Cost-effective: Flat belt conveyors are more affordable than other types of conveyors, making them a cost-effective solution for many businesses.

- Versatile: Flat belt conveyors can be used for a wide range of applications, from assembly lines to product sorting.

- Efficient: Flat belt conveyors are designed to transport materials quickly and efficiently, helping to increase productivity and reduce downtime.

- Reliable: Flat belt conveyors are built to last and are known for their reliability, making them a long-lasting solution for your conveyor needs.

Flat Belt Conveyor Price

Dev Engineering Manufacturers And suppliers of Flat Belt Conveyor the best quality And Best Price According to customers’ requirements In All Over India Due to rich industry skills and experience, we have been accomplished to provide our valued customers with the best quality range of Flat Belt Conveyor

Flat Belt Conveyor Manufacturers in India

Yes, Dev Engineering is indeed one of the leading manufacturers of flat belt conveyors in India. The company is known for its high-quality products and customized solutions for various industries. Dev Engineering has a team of experienced engineers and technicians who use the latest technology and design methods to manufacture conveyors that meet the specific requirements of their clients. Their flat belt conveyors are known for their durability, reliability, and efficiency, making them a popular choice among industries in India.

FAQs

What is a flat belt conveyor?

A flat belt conveyor is a type of conveyor system that uses a flat belt to transport materials or products from one location to another. The belt is supported by either a roller bed or a slider bed and is pulled along its length by a drive pulley, powered by an electric motor. Flat belt conveyors are commonly used in industrial, manufacturing, and material handling applications to move boxes, packages, and other items efficiently and safely.

What are the different conveyor belt types?

There are several types of conveyor belts, including:

1. Flat Belt Conveyors: A flat belt conveyor is a basic type of conveyor system that uses a flat belt to transport materials or products.

2. Modular Belt Conveyors: Modular belt conveyors are similar to flat belt conveyors but use a modular plastic belt instead of a flat belt.

3. Cleated Belt Conveyors: Cleated belt conveyors have raised edges, or cleats, that help to keep items on the belt while they’re being transported.

4. Magnetic Belt Conveyors: Magnetic belt conveyors use a magnetic field to transport ferrous materials and objects along the conveyor belt.

5. Inclined Belt Conveyors: Inclined belt conveyors are used to transport materials or products up or down an incline.

6. Roller Bed Conveyors: Roller bed conveyors are similar to flat belt conveyors but use rollers instead of a flat belt to transport materials or products.

7. Slider Bed Conveyors: Slider bed conveyors are similar to flat belt conveyors but use a slider bed instead of a flat belt to reduce friction and wear on the belt.

Each type of conveyor belt has its own unique benefits and uses, and the choice of conveyor belt type depends on the specific needs of the application.

What is flat belt?

A flat belt is a type of conveyor belt that is flat in shape and used for transporting materials or products from one location to another. It is usually made of a flexible material such as rubber, leather, or fabric and is supported by either a roller bed or a slider bed. The flat belt is pulled along its length by a drive pulley, which is powered by an electric motor. Flat belts are used in a variety of industrial, manufacturing, and material handling applications due to their simplicity and versatility. They are commonly used to move boxes, packages, and other items efficiently and safely.

What are the applications of flat belts?

Flat belts have a wide range of applications in various industries due to their simplicity, versatility, and low cost. Some of the common applications of flat belts include:

1. Material Handling: Flat belts are widely used in material handling applications to move boxes, packages, and other items from one location to another.

2. Manufacturing: Flat belts are used in manufacturing processes to transport materials and products between stages of production1.

3. Agriculture: Flat belts are used in agriculture to transport grains, seeds, and other crops.

4. Food Processing: Flat belts are used in food processing to transport food products, such as baked goods and packaged food.

5. Textile Industry: Flat belts are used in the textile industry to transport fabric, thread, and other materials.

6. Packaging Industry: Flat belts are used in the packaging industry to transport packaged goods from one station to another.

7. Mining: Flat belts are used in the mining industry to transport minerals, rocks, and other materials from one location to another.

8. Printing Industry: Flat belts are used in the printing industry to transport paper and other materials through printing presses.

These are just a few examples of the many applications of flat belts. The specific use of flat belts depends on the requirements of the application, such as the type of material being transported, the distance it is being transported, and the speed and efficiency required.